KT Plastics’ “I-BOND” Cer-Met coatings are offered through our partnership with AVES Industries. I-BOND is a hard-face, ceramic-metallic coating with excellent wear, chemical, abrasion and erosion resistance.

General Description

Aves “I BOND”, is a tightly controlled thermal process carried out in a controlled atmospheric furnace where the workpiece is brought into intimate contact with a proprietary blended media specifically formulated for the customers’ requirements of case chemistry, hardness and depth.

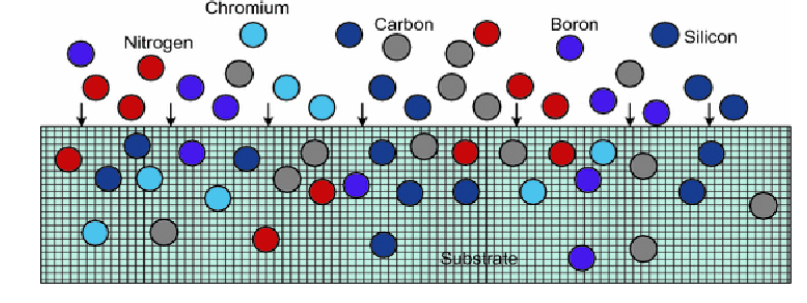

Here is a quick overview of this process. The workpiece is prepared and placed inside an atmospheric-controlled reactor in intimate contact with the blended media. Upon reaching the critical activation temperature, the elements of the blended media begin to migrate into the microstructure of the workpiece, effectively re-alloying the surface. As the various elements in the blended media encounter the activated surface of the workpiece, they migrate into and react with the microstructure to produce various complex ceramic and metallic (Cer-Met) compounds. These stable Cer-Mets become part of the workpiece microstructure, imparting to it a tough, wear-resistant, low coefficient of friction, chemically resistant surface.

Requisite Element Rich Environment in Plasma, Ion, Vapor Forms

This tough, wear-resistant, hard, (1600-2000HK), Cer-Met case, is metallurgically anchored to the workpiece and exhibits a root-like transition zone providing an anchoring profile of the case to the base material that is very resistant to cleavage along its transition zone.

Aves “I BOND” process, being precisely controlled, produces repeatable results time after time with 40+ years of loyal satisfied customers who can’t find another process which consistently provides the level of performance their application requires.

Aves “I BOND” Benefits:

- High hardness (1600-2000 HK) depending on base material.

- High resistance to temperature (up to 2000°F)

- Increase corrosion resistance to acids (especially HCL)

- Significant reduction in coefficient of friction (typically 60%)

- Surface can be polished to a high finish

- Eliminates galling and tendency to cold weld

- “I BOND” process can be selectively applied to and masked from specific areas

- Surface treatment can be uniformly applied to irregular shapes

- Heat treatable materials can be fully hardened after processing

- Suitable for a broad range of materials

- Uniform case depths of diffusion layers are controllable

Materials favorable to the Aves “I BOND” Process:

List below is not all-inclusive:

Ferrous Metals

- Carbon steels

- Low-alloy steels

- Tool steels

- Ferritic & Martensitic SS

- Gray & ductile cast iron

Non-Ferrous Metals

- Tantalum

- Titanium

- Tungsten

- Niobium

- Molybdenum

Ni Based Alloys

- Super Duplex

- Elgiloy

- Inconcl 625 & 718

- Hastalloy

- Nimonic 80A

Typical applications for Aves “I BOND” include:

Oil & Gas Components

- Production tubing components

- Frac / Lo-Torc valve components

- Coal / Oil burner nozzles

- Shaft wear sleeve

- Nozzles

- Plungers

- Sand transfer augers / tubes

- Seats

- Gears

- Rollers

- Shafts

- Mud motor rotors

- Slurry / sand pump impellers, housings, stuffing box, cover plates

- Blender / mixer paddles

Tooling

- Forging dies

- Forming dies

- Extrusion dies

Call KT Plastics Today

At KT plastics, we can use a variety of coatings on the finished components so that they have added durability, a nice finish, and are the right color. If you need custom parts manufactured and coated, we want to know all about it. Call us at 580-434-5655 to tell us about your project.